1. Homemade Powder Coating Booth Overview and Components

A Homemade Powder Coating Booth is a DIY enclosure designed to safely contain overspray during coating projects. Key components include a sturdy frame (wood or metal), ventilation fans, electrostatic grounding systems, reusable filters, and adjustable lighting. Builders often use cost-effective materials like plywood, PVC pipes, or repurposed cabinets to create a functional workspace.

2. How a Homemade Powder Coating Booth Operates

The Homemade Powder Coating Booth uses exhaust fans to create negative airflow, directing overspray toward filters that trap excess powder. Grounded surfaces ensure electrostatic adhesion, while proper lighting enhances visibility. Filters can be cleaned to recover up to 70% of unused powder, reducing waste.

3. Cost Factors for Homemade Powder Coating Booths

Total costs (150–1,200) depend on materials, size, and ventilation power. Basic plywood booths cost 150–400, while metal-framed setups with industrial fans range from 500–1,200. Optional upgrades like HEPA filters or LED lighting add 50–200.

4. Applications of Homemade Powder Coating Booths

Ideal for small-scale projects: automotive parts (wheels, engine components), bicycles, tools, and home decor. These booths provide hobbyists and small workshops with a controlled environment for durable, professional-quality finishes.

5. Choosing the Right Homemade Powder Coating Booth Design

Prioritize fire-resistant materials (e.g., metal sheets). Ensure ventilation rates (150–300 CFM) match project size. Opt for modular designs for easy storage. Include grounded worktables to enhance electrostatic efficiency.

6. Maintenance Tips for Homemade Powder Coating Booths

Clean filters after each use to maintain airflow. Inspect fan motors monthly for dust buildup. Check electrical grounding connections regularly. Replace damaged panels or worn seals to prevent powder leakage.

7. Customizing a Homemade Powder Coating Booth for Specific Needs

Expand frame dimensions for larger parts. Add multiple exhaust ports for high-volume projects. Integrate sliding doors or adjustable shelves for versatility. Use IoT-enabled sensors to monitor humidity and airflow in real time.

8. FAQs About Homemade Powder Coating Booths

Q: Is a homemade powder coating booth safe for indoor use?

A: Yes—with proper ventilation (200+ CFM fans) and fireproof materials to minimize risks.

Q: Can I reuse powder collected in a homemade booth?

A: Yes—filters capture up to 70% of overspray, making reuse cost-effective.

Q: What size booth is best for car parts?

A: A 6x4-foot homemade powder coating booth accommodates most automotive components.

Q: How to reduce static electricity in DIY booths?

A: Install copper grounding strips and anti-static flooring.

Q: Are homemade booths suitable for metallic powders?

A: Yes—ensure filters are fine enough (10–20 microns) to capture metallic particles.

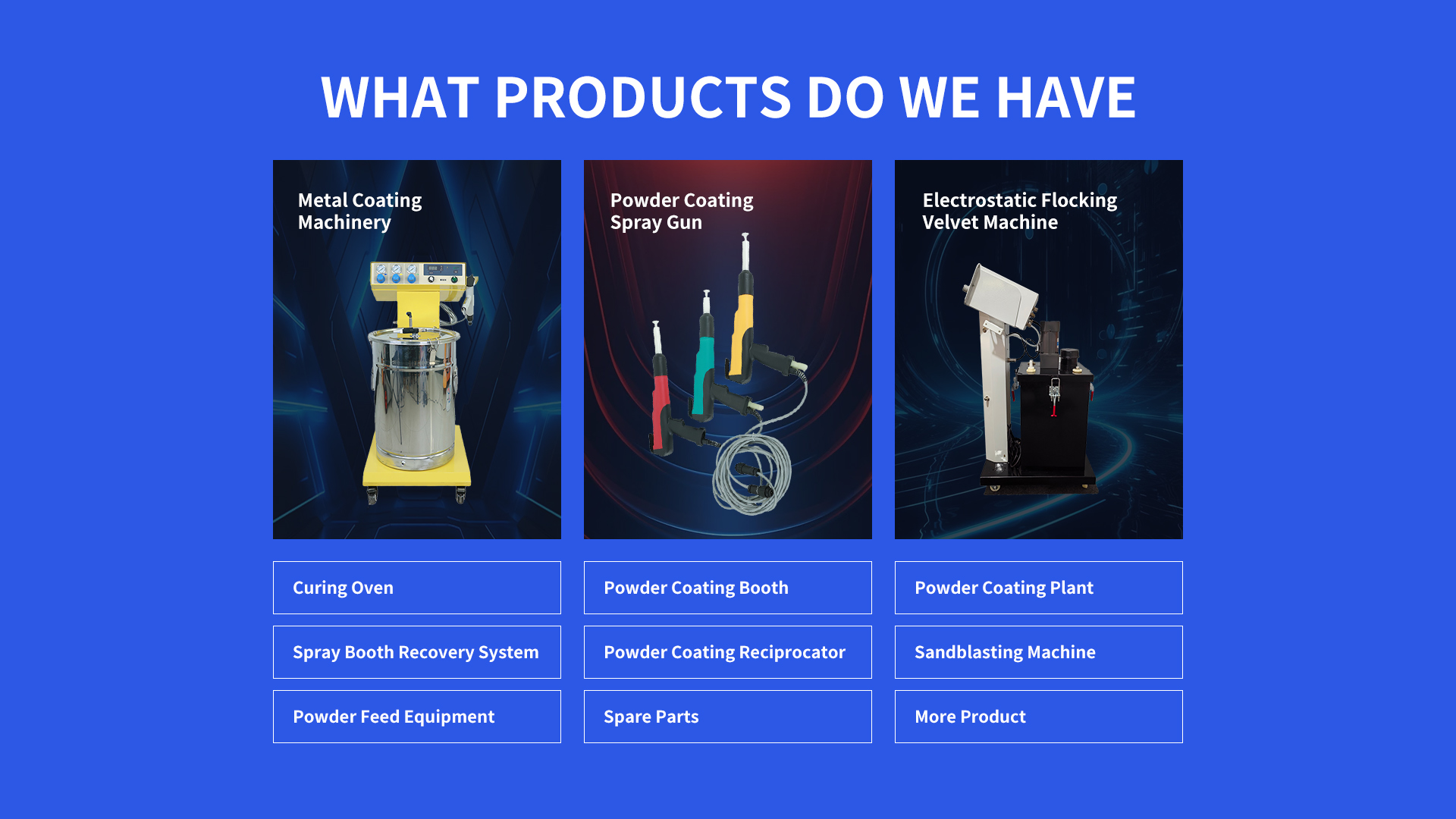

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com